Our Laboratory is equipped with world class and best equipment’s for testing the Activated Carbon. A well-crafted Quality plan is in place right from the incoming charcoal, to the various unit operations, till to the finished product, it is documented for its identification and traceability.

We follow ASTM analysis and testing procedures. Our QA department is equipped with latest testing equipment as per the ASTM procedural norms.

We have a well-established quality control department lead by a team of experienced personnel assures the customer specifications are met in lieu with Quality, Quantity and Presentations.

| Parameters | Testing Method / Equipment |

|---|---|

| PARTICLE SIZE DISTRIBUTION | ASTM D-2862, (For PAC: CC/SOP/22 Wet Laser method) |

| MOISTURE CONTENT | ASTM D-2867 |

| APPARENT DENSITY | ASTM D-2854 |

| TAPPED DENSITY | ASTM D 8176 |

| CARBON TETRACHLORIDE | ASTM D-3467 |

| BUTANE ACTIVITY | ASTM D-5742 |

| ASH CONTENT | ASTM D-2866 |

| BALL PAN HARDNESS NUMBER | ASTM D 3802 |

| IODINE NUMBER | ASTM D-4607 |

| MEAN PARTICLE DIAMETER | ASTM D-2862 |

| pH | ASTM D-3838 |

| BREAK THROUGH CAPACITY | AS PER ASTM |

| CONTACT PH | ASTM D-6851 |

| PLATELET CONTENT | AARL/ AAC |

| ROLLING BOTTLE ATTRITION | AARL/CC |

| TURBIDITY (NTU) | CC/SOP/38 |

| SURFACE AREA | BET M2/g |

| PORE VOLUME | BET N2 |

| DUST INDEX | CC/SOP/20 |

| WATER SOLUBLE ASH | ASTM D-5029 |

| MAGNETIC PARTICLE | CC/SOP/ 17 |

| METHYLENE BLUE VALUE | JIS K 1474 |

| ELEMENTAL ANALYSIS (Like: Ag/Fe/Cu/Cr/Au/Sio2 etc.) | ATOMIC ADSORPTION SPECTROPHOTOMETER |

| SILVER LEACHING | CC/SOP/50 |

| AMMONIA TESTING |

Our Quality Assurance Laboratory consists of the best equipment's and some of them are

Atomic Adsorption Spectrophotometer (AAS) is an analytical technique used to determine how much of certain elements are in an Activated Carbon sample. AAS features high-sensitivity analysis with flexible system configuration along with HVG unit. Elements like Silver / Iron / Gold / Potassium / Calcium / Copper / Chromium / Aluminium / Antimanic / Tin / Arsenic / Nickel etc can me measured in our AAS.

Ultraviolet-Visible-Near Infrared (UV-Vis-NIR) spectroscopy is a technique used to determine the optical properties (reflectance, absorbance, and transmittance) of Activated Carbon.

Here activated carbon sample is treated with water and the leached water were tested in the UV -Spectrometer to analysis turbidity / transmittance / absorption etc.

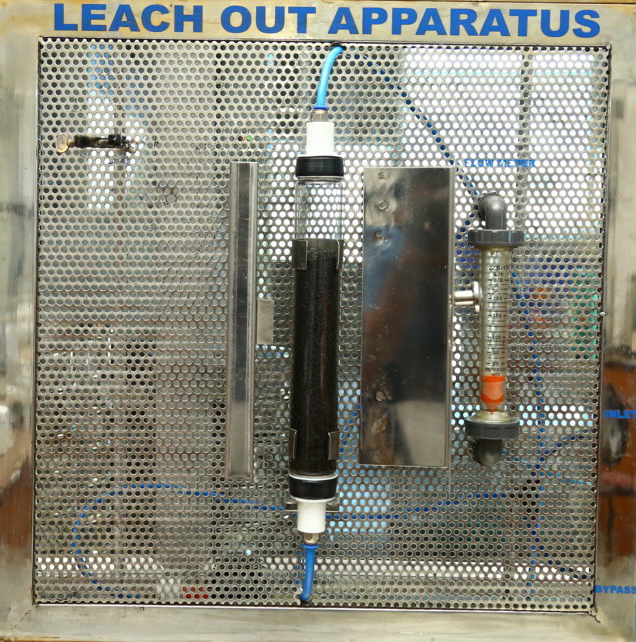

Leaching apparatus, it is an apparatus, it consists of flowmeter and carbon column rig. The carbon rig is filled with activated carbon sample then it subjected water or some other solution (as per requirement) flow through out the carbon bed. Were leach of element or removal of impurities, colour, odour may happen that is elution process may happen. The leach-out / eluate will be analysed in the photometer / AAS.

Leaching analysis: silver removal / Ammonia removal / De-Chlorination half-length value etc.

Turbidity refers to the concentration of undissolved, suspended particles present in a liquid measured in Nephelometric Turbidity Units (NTU). The microprocessor-based waterproof Turbidity meter is an easy-to-use turbidimeter that can measure the NTU of Activated Carbon. Using an Infrared light source, it delivers laboratory accuracy with a resolution of 0.01 NTU across an extended range of up to 100 NTU

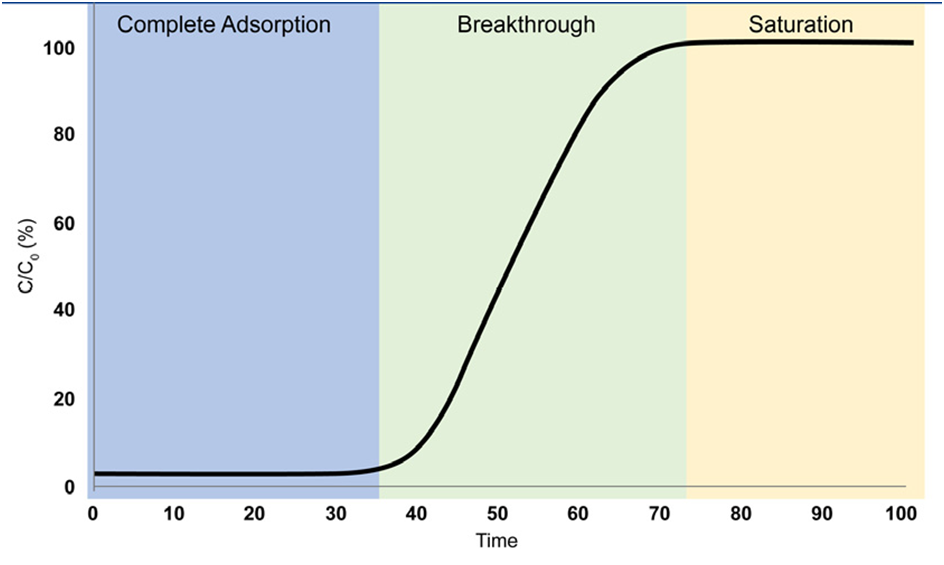

Breakthrough analysis is a powerful technique for determining the adsorption capacity of Coconut Shell based Steam Activated Carbon. Dynamic breakthrough adsorption provides many advantages over static adsorption measurements.

Examining A Breakthrough Curve,

Surface Area is an intrinsic property of porous materials that can reveal important information regarding the usefulness of a material for an application.By means of Physical adsorption, Surface Area is calculated since physically adsorbed molecules are not restricted to specific sites and are free to cover the entire Surface. This process is reversible.Typically, nitrogen gas is adsorbed at cryogenic temperatures (liquid nitrogen). Based on the amount of gas adsorbed (adsorbate) at a given pressure, the BET equation is used to calculate the number of adsorbed gas molecules that would be required to form a monolayer on the surface.

The Mastersizer 3000 uses the technique of laser diffraction to measure the particle size and particle size distribution of materials. It does this by measuring the intensity of light scattered as a laser beam passes through a dispersed particulate sample. This data is then analyzed to calculate the size of the particles that created the scattering pattern. Three main elements enable the system to consistently and reliably deliver the accurate, robust particle sizing data that is central to the effective operation of so many industrial processes.

Hana Photometer is a compact, multiparameter photometer for use in the lab or in the field. The meter is one of the most advanced photometers available with an innovative optical design that utilizes a reference detector and focusing lens to eliminate errors from changes in the light source and from imperfections in the glass cuvette. This meter has 60 different programmed methods measuring 37 key water quality parameters and also offers an absorbance measurement mode for performance verification and for users that would like to develop their own concentration versus absorbance curves.

To save valuable laboratory benchtop space, the Hana Photometerdoubles as a professional pH meter with its digital pH/temperature electrode input. Now one meter can be used for both photometric and pH measurements.